HEXUS had the Intel Core i9-10900K, and Core i5-10600K, under scrutiny in the labs last week. Intel's latest enthusiast/gamer champ choice is a 125W TDP (but consumes up to 200W under load) processor, packing 10C/20T, and clock speeds boosting as high as 5.2GHz (claimed 5.3GHz TVB peak, and 4.8GHz all-core boost). We noted that Intel improves thermals and headroom by using thinner silicon and thicker heatspreaders for this 10th gen Core desktop line. For our tests we used the capable Noctua NH-D15S air cooler with 140mm PWM fan.

Ours was a pretty capable off the shelf setup, but what could be achieved by delidding the processor, adding liquid metal thermal compound, and strapping on a chunky LCS? YouTuber der8auer has stepped in to answer that question and interestingly compares the results vs previous gen Intel Core i9-9900K (8C/16T, 95W) and i7- 8700K (6C/12T, 95W) processors.

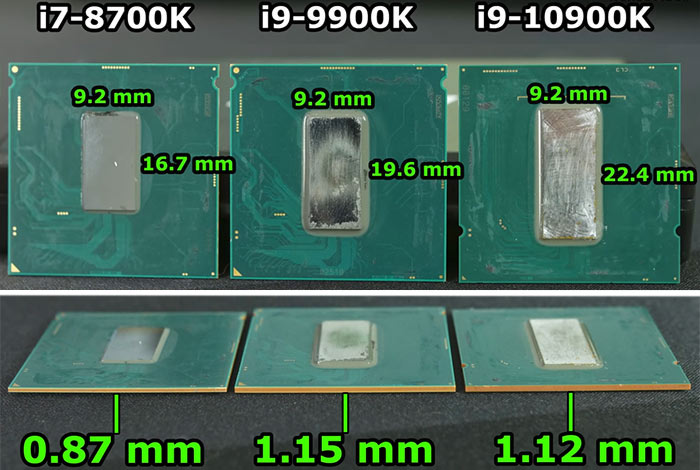

The DeLid DieMate 2 had to be rotated 180 degrees and used a second time, due to the softness of the Indium solder. Once off it was immediately apparent that the Intel Core i9-10900K die was about the same width as the 9900K, but taller. Some comparative measurements were taken by der8auer, and I have included screenshots of these comparisons below.

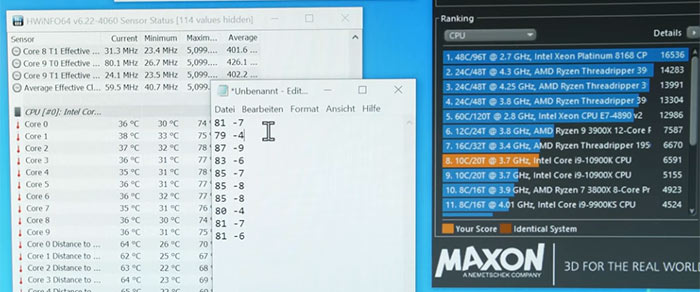

After de-lidding, measuring and other comparisons, der8auer went ahead and added liquid metal thermal compound to the chip die/HIS, and he re-ran the suite of tests which were undertaken ahead of this process. Below you can see der8auers notes showing the new temperatures of the 10900K cores with a Notepad superimposed showing the previous core temperatures and observed differential. The delidding and liquid metal change resulted in processor cores running between 4 and 9 degrees cooler.

While the above temperature results look encouraging, the OC expert warns uses who go through the process not to expect to be able to get 200MHz extra max clocks from their processors, rather any benefits "will be quite small".