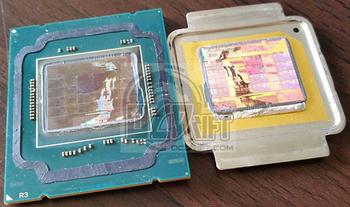

Malaysian overclocking enthusiast Kevin Owi (Owikh84) has de-lidded what he claims to be Intel's upcoming Core i7-5960X chip. He wanted to take a peek at what the processor would look like after its Integrated Heat Spreader (IHS) was removed and find out more about the improved Thermal Interface Material (TIM) that Intel boasts about. I've embedded his main feature picture directly below.

The Intel Core i7-5960X is one of Intel's upcoming 'Haswell E' processors so Owihk84 did well to get his hands on it and then take the risk of de-lidding this purported US$999 part for the curiosity of the PC enthusiast community. This Core i7-5960X is going to be the flagship of the trio of initial Haswell E launch processors, boasting 8 cores and 16 threads, 20MB of L3 cache and a regular/turbo clock speed of 3.0GHz/3.3GHz.

Looking closely, the 22nm chip pictured above, appears to have 12 core modules (the 3x4 grid) so four of these must be disabled. That's still going to consume a lot of power in a small area with a purported TDP of 140W. So the TIM will be very important to make the best use of the cooling system you employ to get the heat out of a system based on one of these chips.

Owikh84 removed a strong layer of conductive epoxy which Intel had used to fix the Integrated Heat Spreader (IHS) to the chip die. This 'solder' is said to offer much better conductivity than the TIM used in the likes of the Intel Core i7-3770K, 4770K, and 4790K for example.

The chip you see under the knife in this picture is expected to be officially released sometime in September this year. When this chip does become official we won't be putting it under the knife but it will definitely be put under the HEXUS benchmark microscope.